Description

Purge larger diameter pipes faster than ever

Used for stainless, duplex, chrome steels, titanium, nickel and other alloy materials, the PPM Pipe Purge Bag System™ systems enable high speed welding of larger diameter pipe joints that have to be purged.

Designed to enable the user to produce high quality, reliable and repeatable welding of stainless steel tube and pipe joints to ensure a very fast weld purge time and a very high quality weld root, free from oxidation and discolouration.

A 36″ diameter pipe will purge to below 0.1% oxygen in less than 10 minutes and all smaller pipes correspondingly faster.

Dramatic savings of time, gas and money can be made by using these systems.

Due to the quality of the materials used, the Rapid Purge™ systems can be used over and over again urther reducing manufacturing costs.

As with all of the PPM Pipe Purge Bag System inflatable purging systems, the Rapid Purge™ come with pre-set valves, so are ready to use ‘straight out of the box’.

Rapid Purge™ has been developed specifically to enable high speed purging for any pipe welding application.

VIDEOS

PPM Rapid Purge™ System

Features and Advantages

Typical purge times of less than 10 minutes!!!

Friction free coatings allow easy movement through pipes from one joint to another, even around bends and elbows

A central (glow in the dark) strip allows fast and accurate alignment of the system to the centre-point of the weld area

The unique “thru-bore” design of the central sleeve minimises the area to be purged, dramatically reducing the volume of gas required

Ready to use, connects to a dedicated and regulated gas supply. Choose any flow rate up to 80l/min. through the twin pre-set purge valve

The inflatable dams and imbelical hose are covered with a heat resistant material and insulated accordingly for use at temperatures up to 250ºC

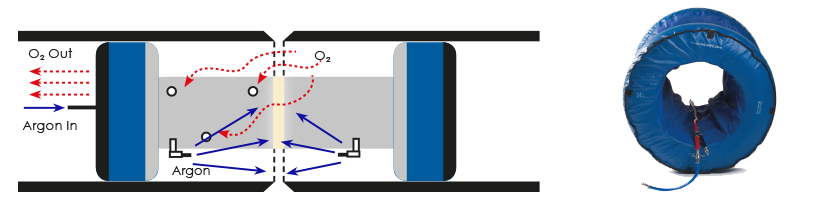

How it works

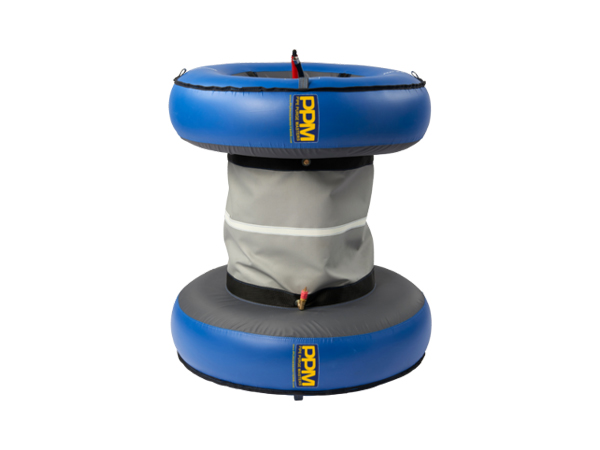

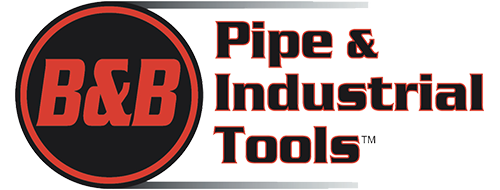

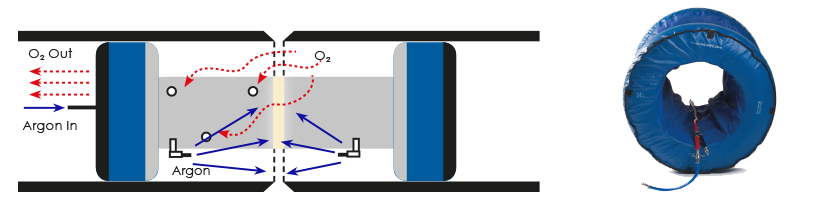

The Rapid Purge™ Inflatable Pipe Purging Systems for pipe and vessel purging comprises a tandem inflatable dam system connected by an umbilical hose and collar to reduce the volume being purged.

A gas exhaust valve is installed between the primary and secondary dam, along with an auxiliary argon purge line.

Each Rapid Purge™ System is covered with heat protective material, so that the higher temperatures closer to the weld do not damage the system.

The robust design of the Rapid Purge™ Inflatable Pipe Weld Purging Systems allows for many years of repeatable trouble free use.