Description

TAG Rim Clamps

Ultra heavy duty reforming and alignment clamp

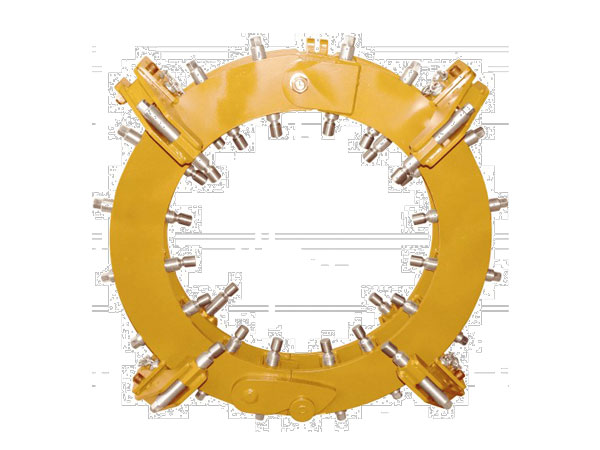

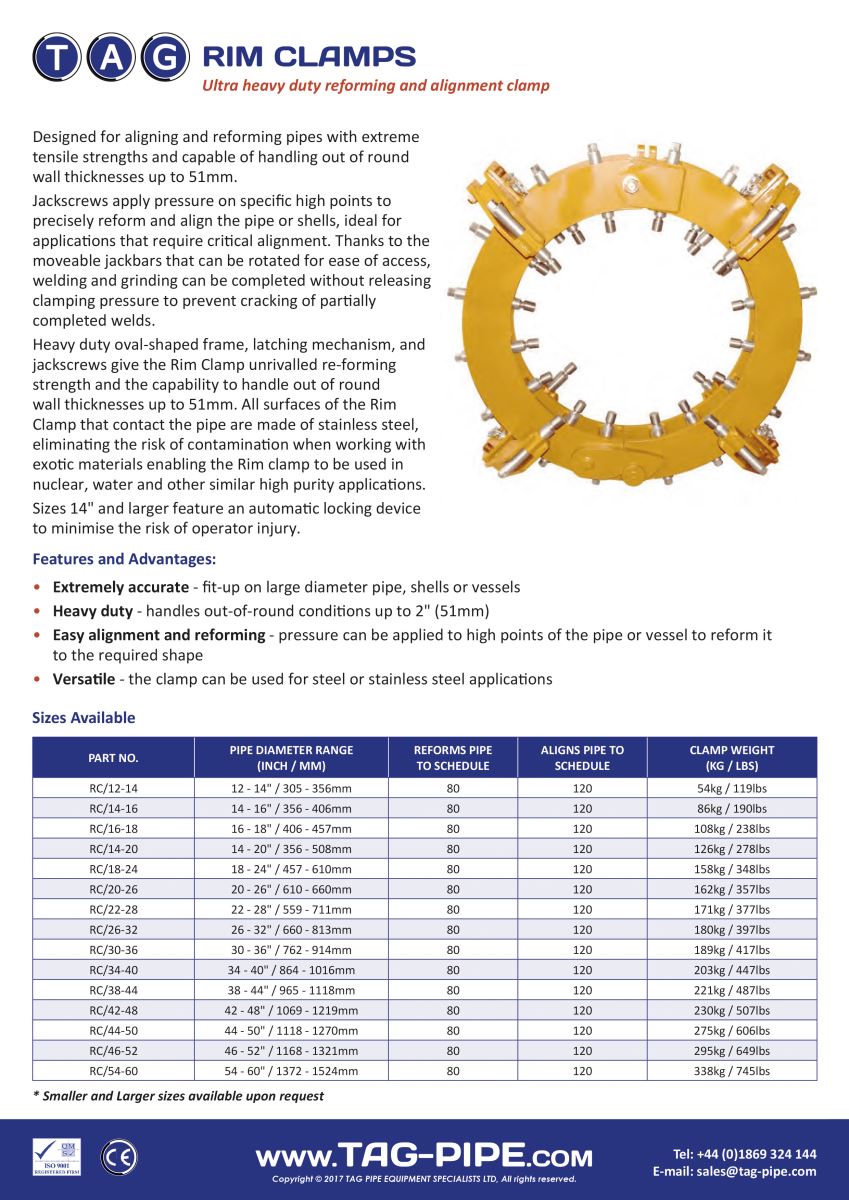

Designed for aligning and reforming pipes with extreme tensile strengths and capable of handling out of round wall thicknesses up to 51mm.

Jackscrews apply pressure on specific high points to precisely reform and align the pipe or shells, ideal for applications that require critical alignment.

Thanks to the moveable Jackbars that can be rotated for ease of access, welding and grinding can be completed without releasing clamping pressure to prevent cracking of partially completed welds.

Heavy duty oval-shaped frame, latching mechanism, and jackscrews give the Rim Clamp unrivalled re-forming strength and the capability to handle out of round wall thicknesses up to 51mm.

All surfaces of the Rim Clamp that contact the pipe are made of stainless steel, eliminating the risk of contamination when working with exotic materials enabling the Rim clamp to be used in nuclear, water and other similar high purity applications.

Sizes 14″ and larger feature an automatic locking device to minimise the risk of operator injury.

Features and Advantages:

- Extremely accurate – fit-up on large diameter pipe, shells or vessels

- Heavy duty – handles out-of-round conditions up to 2″ (51mm)

- Easy alignment and reforming – pressure can be applied to high points of the pipe or vessel to reform it to the required shape

- Versatile – the clamp can be used for steel or stainless steel applications