Description

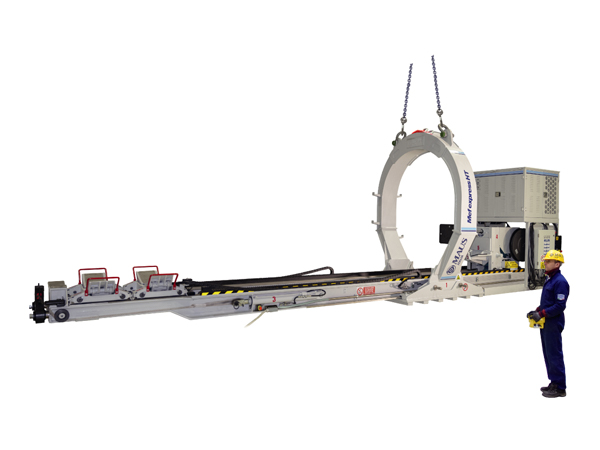

Mef express HT – ensure minimum downtime and protection of the tube bundle during extraction.

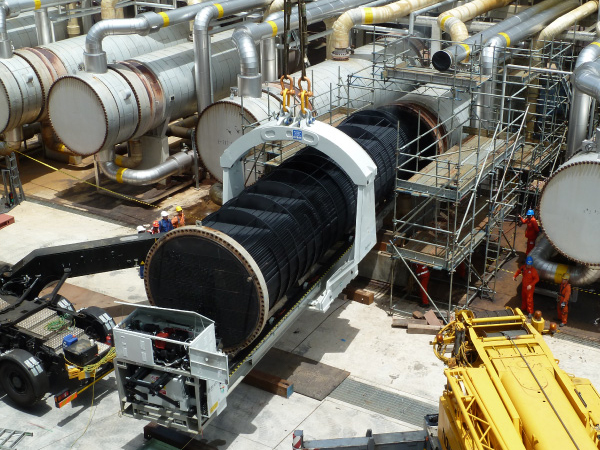

MAUS ITALIA presents, for the extraction and insertion of tube bundles in the plant, a complete new range of Mef express HT aerial tube bundle extractors with dedicated solutions for handling by crane for maintenance at great heights.

Years of evolution of the Mef express product series have allowed the design to be revisited, making the Mef express HT ( High Technology ) aerial tube bundle extractors of today even more lightweight, more exible and easier to handle.

For tube bundles up to 125 T weight.

Mef express HT main features

|

No damage The Mef express HT aerial extractor carefully supports the tube bundle during extraction and insertion and ensures perfect balance along its longitudinal axis, eliminating the risk of damaging the baffles or crushing the tubes. |

|

Operational simplicity The controls on the supplied remote control make the Mef express HT extremely simple and intuitive to use, guaranteeing the operator full control of the extraction or insertion sequence. |

|

Long-lasting epicyclic power The use of powerful planetary gearboxes guarantees greater reliability and robustness than chain systems, thus minimising the need for maintenance. |

Mef express HT main optionals

Mef express HT ensure minimum downtime and protection of the tube bundle during extraction

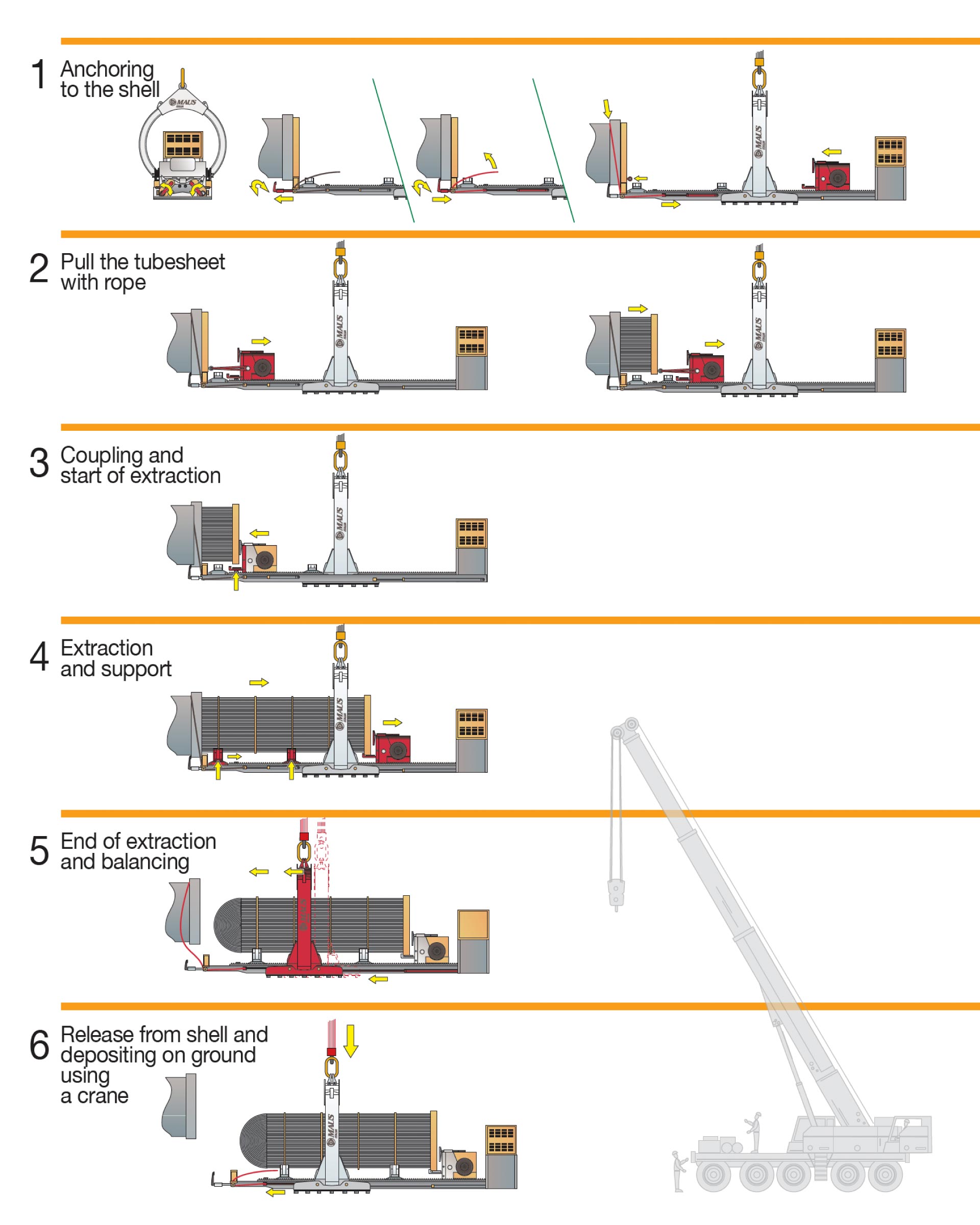

- Adjustable hydraulic vices for anchoring the machine to the exchanger flange. Also available with left and right independent movement (optional)

- Electrowelded steel structure to support the weight of the tube bundle

- Lifting points or lifting the extractor

- Engine unit sized for the selected model (with liquid-cooling optional)

- Support trolleys to support the tube bundle. Also available with hydraulically operated (optional)

- Hydraulic rope tensioning system for safe anchoring of the extractor to the exchanger. left and right side independent movement (optional)

- Remote control for controlling the available hydraulic movements (wireless optional)

Extraction sequence

Easy container transport

For sizes from the Mef express HT 2545/75 up, the lifting ring can be disassembled into 3 parts to allow the extractor to be shipped in Open Top containers and help truck transportation.

Hydraulic balancing system

Two powerful hydraulic pistons allow balancing of the extractor by modifying, if necessary, the position of the frame with respect to the ring attached to the crane.

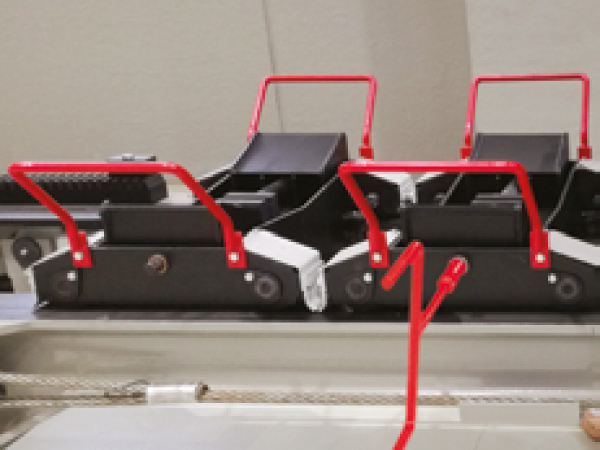

Manual adjustment of the bundle supports

Correct support of the tube bundle is guaranteed by the support trolleys which, resting on the diaphragms, support it safely without compromising its integrity.

Long-lasting epicyclic power

The use of powerful planetary gearboxes (between 1 and 3 according to pulling force) improves reliability and makes possible the increase of pulling force compared to chain systems, thus minimising maintenance of the transmission components.

NEW / PATENTED: Telescopic arms for the thrust and rotation of the tube bundle

Innovative remotely-controlled system for rotating the tube bundle which allows safe alignment the bundle with the shell, avoiding the need for the operator to climb on the Mef express HT during the final insertion phase.

EOC: Electronic Overturning Control system

Innovative control system which allows overhead handling of loads in complete safety by inhibiting any incorrect commands that could compromise the stability of the Mef express HT.

|

ATEX certification on requestThe Mef express tube bundle pullers are available, on request, suitable for use in hazardous areas, complete with an ATEX declaration of conformity covering the whole machine ( motors, electrical system and all machine components ). |